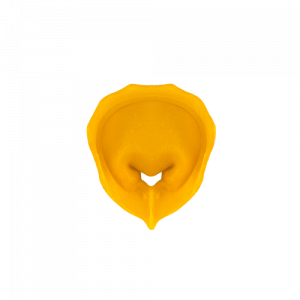

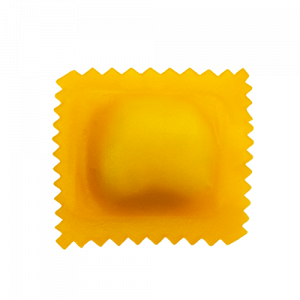

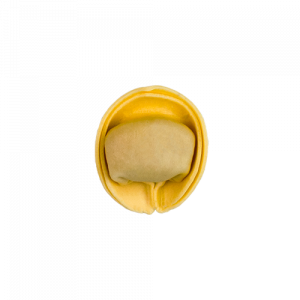

Cottura in pentola

Portare ad ebollizione una pentola d’acqua salata, versare i Tortellini e cuocere per 5 minuti. Condire a piacere e servire in tavola.

Ingredienti

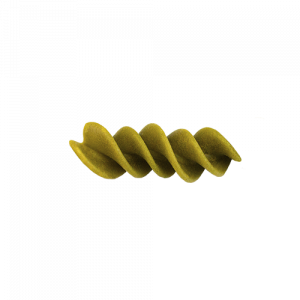

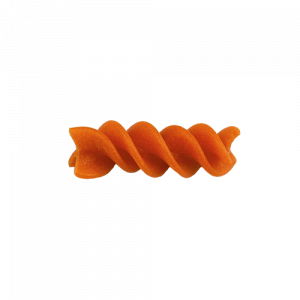

Pasta 70%: preparato per pasta (amido di mais, fecola di patata, farine di legumi [piselli], fibre vegetali [patate, mais, pisello, psyllium], aromi naturali), uovo 24%, acqua, olio extra vergine di oliva.

Ripieno 30%: mortadella (carne suina, trippini suini, sale, zucchero, aromi naturali, antiossidante: E301, conservante: E250), prosciutto crudo 21% (carne di suino, sale, aromi naturali, conservanti [E252, E250]), pancetta 16,5%, (carne di suino, sale, aromi naturali, destrosio, saccarosio, antiossidante: E300, conservanti [E250, E251]), siero di latte in polvere, ricotta (siero di latte, sale, correttore di acidità: E330), pane grattugiato (amido di mais, acqua, lievito di birra, olio extra vergine di oliva, farina di mais, fibre vegetali [psyllium], destrosio, addensanti [E412, E464], sale, zucchero, acidificante: E262, farina di grano saraceno, emulsionante: E471, aromi), formaggio grattugiato (latte, sale, caglio, conservante: E1105 [lisozima da uovo], antiagglomerante: E460), sale.

Può contenere tracce di: pistacchio, sedano e soia.

Specificatamente formulato per persone intolleranti al glutine.

Tabella nutrizionale (valori medi per 100 g)

|

DICHIARAZIONE NUTRIZIONALE

|

VALORE

|

|

|

Energia

|

1162 kJ – 277 kcal

|

|

Grassi

|

10 g

|

|

di cui acidi grassi saturi

|

3,9 g

|

|

Carboidrati

|

35 g

|

|

di cui zuccheri

|

1,3 g

|

|

Fibre

|

3,4 g

|

|

Proteine

|

10 g

|

|

Sale

|

1,6 g

|